AlantumFoams.

Material. Technology. Engineering. Manufacturing. Alantum is the only global manufacturer of alloy foam on a commercial scale. Our facilities in Germany, China and Korea operate with an annual production capacity of 1 million liters of alloy and metal foam, using patented powder-metallurgical and electroplating processes. The result is a reproducible quality with unique characteristics.

Zero

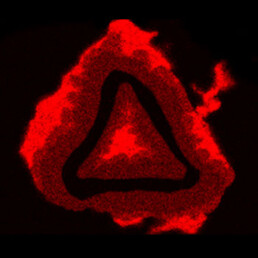

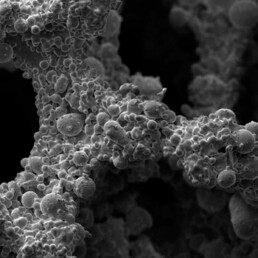

Blocked Pores

Our promise: Show us one single blocked pore and you get a tasty Munich beer for free.

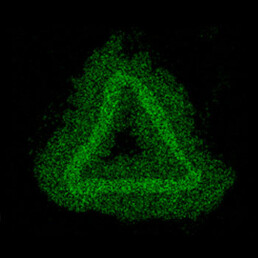

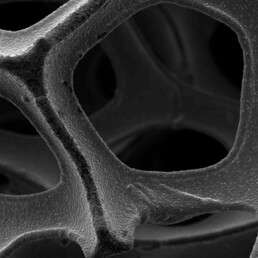

Uniform

Cell Size

Material uniformity and reproducibility are pivotal for meeting and repeating your performance targets.

Scaled

Reproducibility

Operational excellence under quality management systems certified to ISO 9001 and ISO 14001.

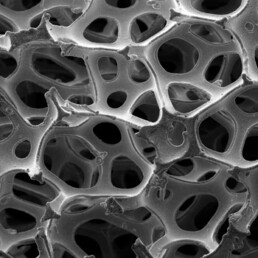

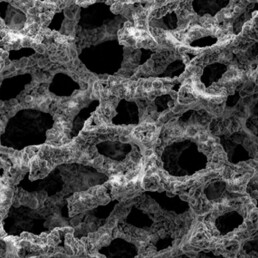

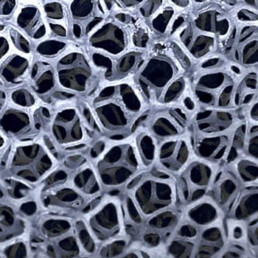

Controlled

Surface Roughness

From smooth struts, controlled metal grain sizes, high-surface morphologies and optimized coating adhesion.

Super

Alloys and Metals

We take pride in our sintering capability, ensuring fully homogenous elemental distribution.

150+

Patents

Innovation on novel materials, process technologies and applications is key to secure FTO for our customers.

Defined.

Alantum metal foam is a 100 % open-porous cellular structure. It unites definition on every level: From micro to macro

Micro - material level

Alantum’s patented plating and powder-metallurgical processes guarantee the highest purity of precious metal foams and the homogenous composition of alloy foams. The tunable material properties of Alantum foams are key for their functionality in various applications, as well as their mechanical, thermal, and chemical resilience.

Meso - structural level

Chemical catalysis, electrocatalysis, emission control, conductive materials, filters, mixers, or burner substrates – Alantum foams can be tailored to any application. The high geometric surface area of Alantum alloy foam, combined with its characteristic surface roughness, makes it an ideal substrate for durable, functional catalyst washcoats.

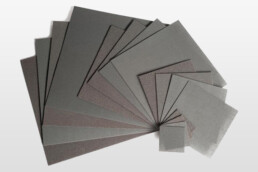

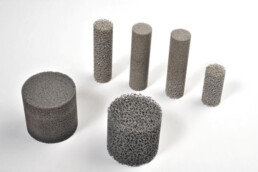

Macro - product scale

Alantum metal foam is produced in sheets of various thicknesses. It can be compressed, joined, cut, stamped, welded, seamed, sealed, filled, and drilled to create almost any 3D shape. We design, engineer and manufacture a wide range of products – from metal foam-micropellets to components made of super-alloy structured composites.

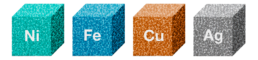

Metals

Base Metals, Precious Metals, Super Alloys. Nickel, Iron, Copper and Silver foams are of special interest for electro- and chemical catalysis. Ag and Cu offer the highest thermal and electrical conductivities.Super alloys foams are known for their tremendous material strengths – used as catalysts carriers, flow fields, and as high-temperature fuel-saving burner media.

Pure Metals

Super Alloys

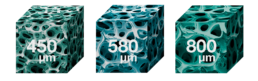

Cell Size

Structure controls Performance. Alantum’s standalone material characteristic is a 100% open porosity. This ensures predictable, reproducible, and controllable results in operation. What’s more, your selection of the right cell size provides full control over pressure drop, mechanical stability, filtration effectiveness, and catalyst activity by means of surface area.

Shape

Tailor-made solutions for your application. From ready-to-use drop in solutions to all-new design concepts. Our portfolio encompasses foam-pellets on millimeter scale to reactor-sized composites. Our engineering team helps you to identify the right material, pick the appropriate cell size, design the best shape, and ensure full manufacturability. Ultimately, our goal is to create the maximum value for our customers.

You need more information, technical data sheets, or material safety data sheets?

Services.

We offer not just a material that can transform reactor performance and energy applications. Alantum builds on the world’s leading store of alloy foam IP expertise and a total customer focus. From inquiry through development, production and installation, we commit to your success at every stage up to implementation and commercial exploitation. Our goal is to develop and deliver the solution that aims to exceed expectation: